Metal Fabrication and Finishing

Full service fabrication,

simple to complex

Capabilities

- Precision metal stamping

- Fabrication

- Finishing (powder coat, wet paint)

- Tooling

- Product development services

- Low to high volume

- Proto shop

- CNC Tube Processing (bending and punching)

Precision Metal Stamping

Die Types

Pierce and blank, bend and form, draw, four slide tooling and cam dies. Press room up to 440 tons, and up to 36" coil width.

Press Room

18 tons to 440 tons, Up to 36" coil width, Coil straightener up to 1/8" thick

Component Size

Length: 0.050” to 60.00” Width: 0.125” to 50.00” Thickness: 0.002” to 0.500” Draw Depth: Up to 7” (175 ton hydraulic) Draw Depth: Up to 4" (440 ton hydraulic)

Material Stock

Thickness: 0.005” to 0.375” Width: 0.250” to 36”

Material

Steel, Spring steel, Stainless steel, Brass, Copper, Tin plate, Pre-plated, Galvanized, Electro-zinc , Beryllium copper, Aluminum clad copper, Aluminum, Titanium, Plastic and Mylar, Wire

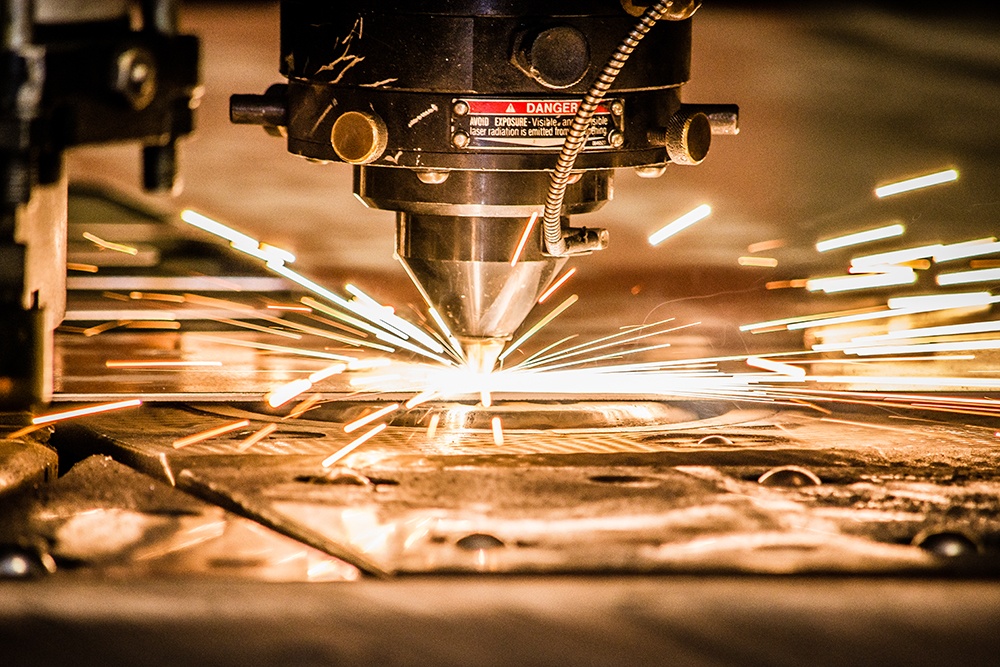

Fabrication

Processes

Laser cutting - CO2 and Fiber, Mechanical shears, Turret punching, Hardware mounting, Forming, Welding, Mechanical finishing

Materials

Steel, Stainless steel, Aluminum, Copper, Galvanized, Brass

Material Stock

Thickness: 0.005” to 0.375” Width: Up to 50” Length: Up to 120” Tolerance: Down to 0.001”

Turret Presses

Laser/turret combination, 22 to 33 ton turret presses, Punching, embossing and forming

Hardware Mounting

Press mounted nuts, spacers and studs, Resistive weld mounted spacers and studs

Welding

Metal inert gas (MIG), Tungsten inert gas (TIG), Stick welding (ARC), Resistance spot welding, Sheet and steel alloys, Stainless steel, Aluminum

Mechanical Finishing

De-burring, Tumbling, Grinding, Sanding and Texturing, Polishing

Finishing

Powder Coating

Manual or automated booth, 5 stage wash process, Length up to 24", Width up to 36", Height up to 96"

Wet Paint

Manual or automated booth

Silk Screen Printing

Multiple Color, Automated, Heat cure, Length up to 36", Width up to 36"

Pad Printing

Multiple color, Automated, UV cure, Length up to 6", Width up to 6"

Tool Shop

3D CAD tool design, Tooling fabrication, Tooling validation and qualification, Tooling repair and refurbishing, Tooling inspection and transfer service

Equipment

CNC, Wired EDM, Surface grinding up to 12 x 24, Lathes, Mills, Heat treat ovens

Product Development Services

Sheet metal component to complete enclosure design, Stamp component design, Tool and die design, Design for manufacturing and fabrication finishing, CAD tools: SolidWorks, ProE and ACAD

Proto Shop

In an effort to continue to expand our sheet metal capabilities and increase our flexibility, Keytronic added a dedicated sheet metal proto type room to provide our valued customers the ability to receive sheet metal prototypes very quickly.

Ready to start something truly amazing?

Contact our sales team today!