Quality

continuous process

improvement

ISO 9001:2015 Certified global facilities ensure that quality standards are achieved and maintained. But for Keytronic, ISO Certification is just the beginning of the quality process.

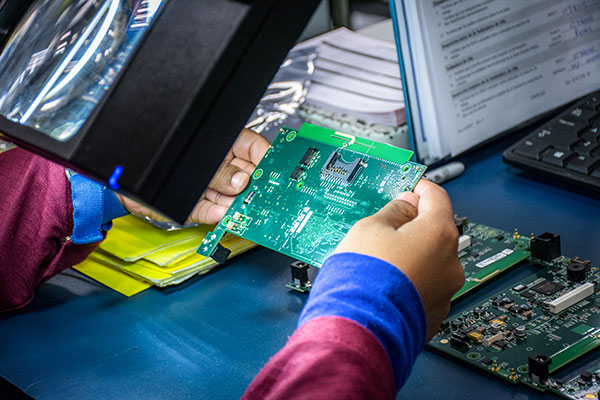

Keytronic's team of Quality Engineers are involved from the beginning of the project, assuring consistency in manufacturing. In-Coming, In-Process, as well as Out of Box quality are measured on a weekly basis in order to improve our manufacturing processes along with those of our suppliers. This data in addition to any customized requested reports, is tracked by product and facility, and communicated to our customer.

Quality Control

- On-line, real time data collection system

- SPC for solder paste volume monitoring

- 100% visual inspection and test

- ESD safe workstation

- Acceptance criteria: IPC-610

- Acceptance criteria: IPC-600 Statistical Process Control (SPC)

Quality Reports

- Out of Box Audit (OOBA)

- Customer Annualized Failure Rate

- In Process

- On-Going Reliability Testing (ORT)

- Rolled Throughput Yields (RTY)

Inspection Equipment

- Coordinate Measuring Machines (CMMs)

- Smart Optical Inspection Equipment

- Optical Comparators

- Optical and X-Ray Inspection Equipment

- Surface Color - Analysis Equipment

- Inspection Magnifications and Assists

- ESD - Monitor and Control

- Miscellaneous Measuring Instruments (Micrometers, Gauges, Plates, Analyzers...etc.)

Our Quality objectives and responsibilities are clearly stated, widely distributed and understood throughout the company.

Keytronic quality initiatives are integral to every phase of the process. Customized testing procedures are developed for each product and all necessary testing is done in-house ensuring the most stringent level of security, confidentiality and delivery requirements.

Ready to start something truly amazing?

Contact our sales team today!